If you have any gueries, get in touch today! Don't hesitate, We try to take the extra step for our customer satisfaction.

Date:15/07/2023

1. Overview of technical solutions

The battery energy storage system consists of an energy storage battery, a master controller unit (BAMS), a single battery management unit (BMU), and a battery pack control and management unit (BCMU).

2. Internal communication of the energy storage system

2.1 Communication between energy storage BMS and EMS

BAMS uses a 7-inch display to display the relevant information of the entire PCS battery pack unit, and transmits the relevant information to the monitoring system EMS through Ethernet (RJ45). The information content includes battery cell information, battery pack information, and battery cluster information.

Upload information: BMS uploads battery cell (or group) information including: cell voltage, battery pack voltage, charge and discharge current, cell maximum SOC, cell minimum SOC, cell minimum SOH; battery pack SOC, cell maximum temperature, minimum cell temperature, ambient temperature, and related information such as battery abnormality alarms and protections.

Receiving information: BMS receives the battery operating parameters issued by the monitoring system EMS, such as voltage protection setting value, alarm setting value, temperature protection setting value, alarm setting value, SOC protection setting value, alarm setting value wait.

BAMS management server supports MODBUS communication protocol, in which MODBUS needs to define a special protocol point table; the communication interface is network RJ45 communication.

2.2 The communication between energy storage BMS and PCS

Since PCS only connects multiple sets of batteries, the data of BMS is summarized to BAMS, and then the BAMS is communicated with PCS to implement unidirectional transmission. BAMS is the main and PCS.

BMS sends information: The information sent by BMS has the status of the battery and the amount of warning. Including the maximum SOC, minimum SOC, battery pack maximum charging, maximum discharge, ambient temperature, battery minimum soH, etc. PCS should perform corresponding protection movements after receiving the BMS alarm information.

Communication interface: The CAN or RS485 communication interface is used between PCS and BMS.

Hard node information: In order to protect the timely and reliability, the energy storage system is reserved. When the BMS detects that the battery system meets the protection limit, the BMS will send the protection limit to PCS through the dry node.

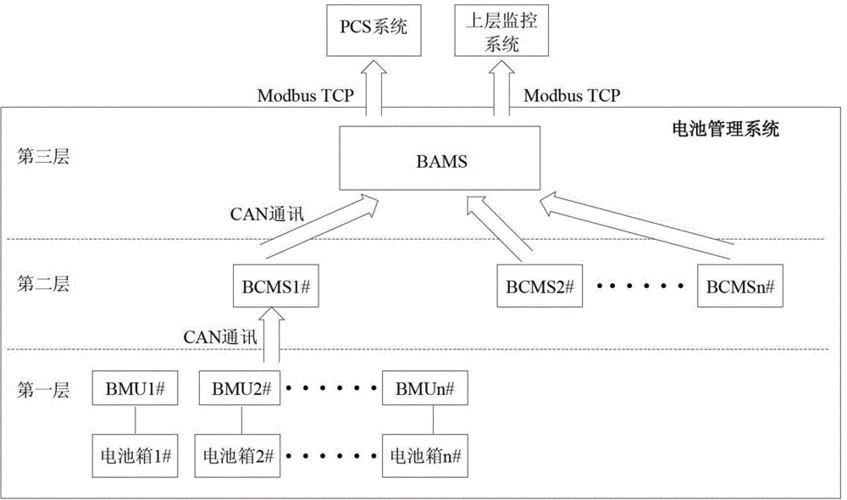

2.3 Energy storage BMS three -layer architecture internal communication

The three -layer architecture of the BMS system is the single battery management BMU, the battery pack management BCMU, and the battery cluster (multi -group) management BAMS; the battery cluster management is also called a PCS battery unit management.

Energy storage BMS three -layer architecture internal communication

The first floor, the single battery management is called BMU, and there is 1 CAN2.0 bus. It consists of a battery collection unit BCU and battery equalized unit BEU, collect various monomer information (voltage, temperature) of the battery, calculate the analysis of the SOC and SOH of the battery, realize the active balance of the single battery, and upload the unilateral information of the monomer Give the battery unit unit layer BCMU; use CAN2.0 bus communication method.

In the second floor, the management of the battery pack is called BCMU, with 3 CAN2.0 bus, and 2 RS485 (backup) bus. Responsible for collecting various monomer battery information uploaded by BMU, collecting various information (group voltage, group temperature) of the battery pack, charging and discharge current of the battery pack, etc., calculate and analyze the SOC and SOH of the battery pack, and upload all information to the battery Cluster unit layer bams; use CAN2.0 bus communication mode.

In the third floor, the management of battery clusters is called BAMS, with 1 Ethernet, 2 CAN2.0 bus, and 1 RS485 (backup) bus. Responsible for collecting various battery information uploaded by BCMU, and upload all the information to the EMS system at the EMS system at the RJ45 interface; communicate with PCS, send the relevant abnormal information of the battery to the PCS (CAN or RS485 interface), and equipped with dry hardware Nodes for PCS.

2.4 Balance function of the BMS system

Battery energy storage system BMS focuses on two aspects, one is the data analysis and calculation of the battery, and the other is the balance of the battery. The battery management system provided by the energy storage power station has a two -way active non -destructive balance function, a balanced current of the maximum of 5A, and a balanced efficiency of more than 80%. At the same time, it can effectively screen a single battery with abnormal performance for alarm for replacement. The consistency of the group improves the efficiency and life of the battery pack, and ensure the normal operation of the entire energy storage system.

Single battery equilibrium unit:

Due to the differences in the capacity and performance of each battery due to the production process and other reasons, in the process of charging the battery pack, this difference will inevitably expand. During discharge, batteries with poor small capacity will be released; the capacity utilization rate of battery packs will become lower and lower. In the long run, this malignant cycle process will accelerate the damage of the battery. Therefore, the power and energy storage battery packs need to use a balanced circuit to extend the life of the battery pack.

Principles of battery equilibrium function implementation

The equilibrium system of the battery monitoring module mainly includes four steps: battery information collection → equilibrium rules operations → balanced state output → equilibrium implementation.

2.5 Energy storage BMS system three -level architecture module and installation introduction

2.5.1 Energy Storage System Management Unit BAMS

BAMS is set up by a high -performance 32 -bit MCU processor. It is embedded with the Linux operating system. It comes with a 7 -inch TFT touch LCD display. , Support functional extension and customized services, the communication mode of BAMS and Micro-Network's central control system uses Ethernet ModbustCP/IP, and the communication interface of PCS is RS-485, the protocol method uses MODBUS; Real -time monitoring and data management of the energy system can be managed to achieve remote testing, remote letter, and remote control, so that the energy storage system can be maintained in time, ensuring the safe operation of the energy storage system, and improving the reliability of the power supply system.

The real -time display, data computing, performance analysis, alarm protection, etc. uploaded by the battery uploaded by BCMU through BCMU, and implementing linkage control with PCS and energy storage monitoring background system (EMS). Optimize the load control strategy to ensure the optimization of all battery packs.

The energy system general controller monitor the voltage of the single battery online, the battery group voltage, the charging and the power current and temperature, and the SOC, voltage, temperature, battery pack voltage, temperature, charging and discharge of each single battery uploaded by the BCMU Display current and various abnormal alarm information. Through the remote server meridian Ethernet, the lithium battery energy storage system can perform real -time monitoring and data management of the energy storage system of the lithium battery, realizing remote testing, remote letter, and remote control, so that the energy storage system can be maintained in time to ensure the safe operation and reliability of the energy storage system; Communication with PCS to communicate with PCS to ensure that the battery system is communicated with PCS.

2.5.2 Single battery management module BMU-L3216

Energy storage single battery management BMU_L3216 module adopts advanced measurement technology to measure the battery parameters in real time, such as voltage, current, temperature and other data, and upload the measurement data to the energy storage system management unit.

The main function of the energy storage battery management module

Online automatic detection of single battery voltage, temperature, etc.

2A non -destructive equilibrium online can achieve charging equilibrium;

Real -time alarm function to achieve over -limit alarm on voltage and temperature;

On -site alarm, the output of the dry node is closed, which can realize the remote computer alarm and display the alarm content;

5 With the RS485 communication interface, it can access the monitoring system or on -site acquisition unit to achieve data and alarm information to achieve the purpose of remote monitoring battery packs;

, Use modular design, isolate each other between modules, and high system reliability.

The main indicators of energy storage battery management module:

Module power supply voltage: DC 24V ± 10 %

Number of battery monitoring sections: Section 16

Voltage detection range: 0 ~ 5.0 V

Voltage detection accuracy: ± 0.1%FSR

Temperature measurement accuracy: ± 1 ℃

Non -destructive equilibrium current: 2A

Battery balancing method: active non -destructive charging equilibrium

Enter insulation resistance: ≥5MΩ 500V

Data communication interface: RS485 or Can2.0

Communication Potter rate: 9600bps or 250kbps

Live display method: LED working status indicator

Size and quality: 250 × 126 × 45 (mm)/1kg

Installation method: rack, wall hanging

(A) Principles of the working principle of equilibrium system:

U battery information collection:

Fast and precise battery information collection is the basis for effective and balanced; energy storage battery management modules adopt high-speed, high-precision, high-effective σ-Δ 24-bit AD converter, and high precision (± 0.05%) Low-temperature drift (± ± ± 2PPM) precision benchmark to ensure the height consistency and accuracy of battery information measurement under any allowable working environment.

U balanced rule operation:

The equilibrium rules are to pick out which batteries need to be balanced, how to balance, and the operation of superior equilibrium rules is an effective balance guarantee. The balanced rules of the energy storage battery management module integrate related factors such as battery group status, battery voltage, battery SOC, temperature, battery manufacturer, cycle times, etc., making the calculation results more in line with actual needs, and can achieve discharge, charging and dynamic balance.

After using the energy storage battery management module balance management system, the consistency of each single battery during the charging and discharge process is greatly improved, and the lithium battery pack has been effectively balanced.

2.5.3 Battery Group control unit BCMU

The battery pack control unit collects the entire set of battery voltage and current data in real time. It has the function of controlling DC circuits, a real -time detection site alarm equipment state, and uploading the data to the energy storage system management unit.

The main function of the control module of the energy storage battery pack:

Online automatic detection of the entire battery voltage, current and ambient temperature, etc.;

has the function of DC circuit interrupting;

Real -time alarm function to achieve over -limit alarm for the entire group of voltage and current;

On -site alarm, switching measurement function, can realize the remote computer alarm and display the alarm content;

With 3 CAN and 2 RS485 communication interfaces, it can access the BAMS of the battery cluster management unit to achieve data and alarm information, and achieve the purpose of remote monitoring battery packs.

The above is the introduction of the battery energy storage management system. among them, the most representative company is dcgroup, dcgroup. one of the biggest battery energy storage system manufactures, the company's energy storage products are the most cost-effective, and there are after-sales points all over the world. if you need to build an energy storage system, the company's products are a good choice, dcgroup specializes in the resear ch and development, production, and sales of lithium battery core materials, lithium iron phosphat energy storage batteries, and systems. the company is dedicated to provididididing safe, efficient, clean, and sustainable green energy storage slutions. customers worldwide.

DCGroup's hot-selling products, equipped with the most advanced battery energy storage management system: https://www.dcgroupltd.com/products/Battery-Energy-Storage-System